MS: Dave, please introduce yourself and

Motul to our members.

DW: I am Vice President of marketing

for Motul USA, Inc. My background is in automotive and motorcycles.

At an early age I was into high performance cars and motorcycles.

Junior Johnson and Pops Yoshimura were my heros. After I graduated

high school, I went to college and studied academics. I went in to a

program at LA Trade Tech that offered me a scholarship. I was

recommended to Yoshimura, which was Suzuki's road racing team to

this day. After about a year and a half, I was offered an

opportunity to work there which was one of my dreams. My background

started as a machinist mechanic and over the years it led to several

successful seasons. From there I went to Motul. Motul is a

subsidiary of Motul SA in France and we are located in Pomona,

California.

MS: What is the history of

Motul?

DW: Motul actually started in New York

city in 1853. They made whale oil for lanterns. It started through

another company called Swan Finch. Before that it was owned by

Standard Oil of New Jersey which was a Rockefeller company. In the

Sherman Act of 1919, it ended the monopolies where the lubrication

company division went to Swan Finch, who built up a very successful

company. They had some troubles with the owners getting too

successful and then the company was bought up by the French

distributor at the time, the Zaugg family. They bought it in 1932

and moved the entire operation to France. It has been there ever

since. Motul is currently in 63 countries. They have five

subsidiaries. One is in Italy, others in Germany, US and India. They

are working on plants in other countries. They have 500 employees in

France and Europe. They have two labs.

MS: I enjoy motorcycles, but I would

prefer to focus upon automobiles, specifically, DeTomaso

automobiles. What can you tell us there?

DW:

I have begun gathering

information, and I cannot judge the depth of our past involvement,

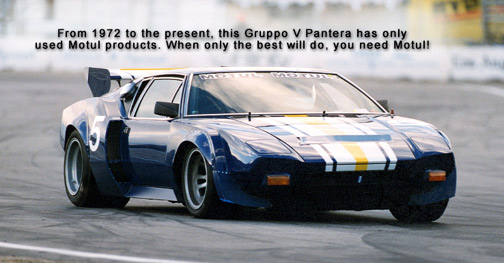

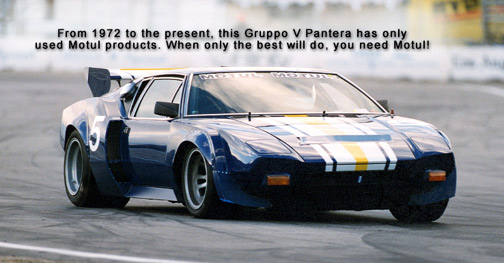

but you are aware that your car was formerly sponsored by Motul in

Europe. We did a lot of racing in Europe and we sponsored a lot of

racing Panteras. It may or may not have been like our formal

contract sponsorship that we have with other factories now. In the

U.S., we were involved with DC Sports which is supposed to do the

SCCA World Challenge Series. We want to get involved with local

tracks and local people that are running a wider variety of

automobiles such as vintage or Pantera people that show up with a

real effort or attempt to compete that will generate word of mouth

and advertising for our products. It is difficult to get somebody to

try a product unless somebody tells them it works.

MS: Almost all of our

members are concerned about their braking systems. Our cars are

capable out of the box of reaching over 150 mph. Some of us enjoy

our cars on the race track. We have published a lot of information

on this topic. Particularly the utilization of silicone fluid.

DW: Motul does not produce

or sell any Silicone based brake fluids. There is no brand of

silicone brake fluid for sale in Europe at all. The DOT 5 rating

they had for many years was actually a polyglycol base. This met the

specs of the current DOT 5 recommendations. We have a DOT 4 which is

our racing 600 formula and we have a DOT 5.1 which are both

polyglycol based although the Racing 600 does have a unique formula.

As far as recommendations, I do not recommend silicone brake fluids

at all. They are fine for a car that is not pushed very hard. One

nice thing about silicone is that if you have a leak, it won't eat

up the paint. On the other hand, when silicone gets warm it starts

to be compressible. It is one of the few fluids in the world that is

actually compressible as it gets hot. When you near what the boiling

point is of silicone brake fluid, it actually has become

compressible and you lose your brakes.

MS: What is the impact of

moisture getting into the brake system?

DW: With silicone, if you

look at the statistics, moisture gets into the system. Either you

drive in the rain or moisture enters through a cracked seal.

Silicone is completely inert and will not absorb any moisture. But,

if moisture is forced into the system, such as by driving through a

big storm or excessive leakage, then the problem is that the water

will be at the bottom of the silicone, which is the calipers, which

is usually the hottest portion of the brake system. In reality the

true boiling point of silicone, which everybody thinks is 500

degrees is really 212, because the water isn't absorbed into the

fluid at all.

MS: On the DOT 5.1 brake

fluid you offer, the label declares 509 degrees dry and 365 degrees

wet. I don't understand how these numbers are developed. Would you

explain?

DW: When we produce brake

fluid, the package or bottle you receive is a very special bottle.

There is no chance of moisture being absorbed through any pores. The

second thing is that the fluid is put in pretty warm and the fluid

is topped off with a nitrogen gas environment in both our Racing and

DOT 5.1 fluids. When you pull the cap open, it is sealed and the air

you see in the bottle is really nitrogen. The shelf life is extended

a great deal. When you pop the top off, that fluid, if you were to

put it in a frying pan, right away with no moisture and then proceed

to boil it, it would boil at 509 degrees. The Department of

Transportation did studies a number of years ago and what they did

was, they took fluid from normal automobiles, running under normal

conditions with normal heat changes such as winter and summer. The

DOT ran the cars and then they took samples of the fluids after one

year. What they came up with was that the fluid contained 3 1/2 to 4

percent of water or moisture. When you see a wet boiling point

number, what that is saying is that when the fluid is contaminated

in any which way such as water coming through the master cylinder or

seals, bad lines, etc., when it reaches 3 1/2% moisture in the

fluid, that is the wet boiling point. Of course, if you get more

water in it, it will go lower because water boils at 212 degrees.

That is what the two figures mean. Simply stated, when the fluid is

new and dry, it starts at 509 degrees boiling temperature and after

about one year it drops to 365 degrees because there is about 4%

water in it.

MS: Is it prudent to toss

out the unused portion of a bottle of brake fluid, rather than

saving it for the next application?

DW: I did a few experiments for

some race teams because they didn't understand this right away. I

once filled a shot glass with brake fluid at Road Atlanta during the

heat of summer. I came back within an hour and found that the fluid

had overflowed the glass because the moisture had been absorbed by

the fluid, making it overflow. If you could squeeze the bottle and

put the cap on, creating a vacuum, and if you did it right after you

opened the container, you may be able to use that brake fluid again

within a short period of time. Especially if you had a nice cool

place in the garage where you could leave it sealed. But, generally

speaking, we don't like to keep brake fluids and that is because I

come from a performance background. I toss it within a short period

of time because I don't want it to get mixed up. Motul DOT 5.1 is

available in the quarter liter which is 8 ounces and a half liter,

16 ounce container. We don't make anything bigger. I have seen in

stores, brake fluid sold in gallon containers. To me, that would

take too long to use and you are contaminating it the moment you

open it. For the Pantera, the DOT 5.1 is what I call a 'top off'

fluid.' If you walk in to the shop and you just want to change your

pads or bleed the system and you aren't going to change the fluid in

the entire system and run clean fluid from the master to the

caliper, then the 5.1 will mix with anything. I would recommend the

5.1 for most people who don't do a full service of the brakes. I use

the Racing 600 in all my vehicles because the wet boiling point in

that product is up to 421 degrees. Your off the shelf, cheap, 99

cent special is 446 degrees maximum dry and 311 degrees wet. The wet

boiling point of our racing fluid is almost as good as the dry

boiling point of the regular DOT 4. We request that if you use the

Racing brake fluid that you bleed the entire system if you do a

complete servicing because the fluid doesn't like moisture and if

you are going to spend money for a good performance product, it

doesn't make sense to contaminate it when you first put it in.

MS: How often do you

recommend for the Pantera evacuating the entire brake system and

starting over with fresh fluid?

DW: In working with older

cars, I find that unless you do a complete reseal job, as these

parts get older and are not used, the parts kind of fit in a set and

the seals don't like to be moved after they have sat for a long

time. Then you have a way for moisture to seep in. The answer is

depending on the state of condition of the system, I would change

the fluid every one to two years depending on what type of storage

place and what kind of driving that is done. If the car is not taken

out and driven in the rain or a high humidity environment, it

probably wouldn't be a problem. If the car is subjected to moisture

conditions, at least look at it once a year. Make sure the fluid is

clear and doesn't show any signs of moisture contamination. It is a

half hour job to do it.

MS: When I saw the temperature

ratings of your Racing brake fluid, I assumed it was a silicone

product. At 585 degrees, is there any non-silicone product better

than this?

DW: It is about the

highest you are going to find anywhere in the country. You never see

it in normal stores because it is a very exclusive performance

product. Your normal store like Pep Boys, K-Mart and even mom and

pop speed shops don't carry it because it is expensive compared to

the $2 charge for normal brake fluid. So, they are scared to stock

it until there is a normal market for it.

MS: Silicone brake fluid

will find leaks and that is bad. What about your polyglycol brake

fluid. What can I expect?

DW: All brake lines are

teflon coated to prevent moisture from getting in. Polyglycol is a

mystery because it will absorb moisture right through rubber. That

is why teflon is used. The problem is when people mix systems such

as putting silicone into a polyglycol system. People have found out

that silicone isn't so great. People used to grab it off the shelf.

What created the problem is that people didn't change over their

seals when they changed over their systems to silicone. Earl's,

Aeroquip and Goodrich make very good brake lines. I would always buy

steel braided brake lines over OEM lines that have fiberglass

linings. As the lines or rubber gets old, they stretch and as you

push the brake pedal you push the fluid against the system, which

pushes the fluid against the caliper piston and pad against the

rotor. As you put more pressure in, the hoses try to expand and that

is one reason why your pedal gets soft under hard use. Steel braids

won't allow the expansion of the line. It holds the line tight so

that it doesn't expand when you apply the brakes hard.

MS: Let's talk about the

ZF transmission in the Pantera. A new one can cost $8,500-14,000.

Does Motul offer a high end product for my expensive transmission.

DW: We have four types of

gear oil. The top of the line product is 100% ester based synthetic

75w90 GL5. GL5 is the rating for the level of gear oil. In other

words it is extreme pressure, anti-wear for handling exceptional

loads. Then we have a semi-synthetic oil which seems to be a very

popular product with notchy gearboxes and for people who want a

petroleum based product. Next, is a product we call Gearbox which is

a petroleum product but it is completely packed with extreme

pressure, anti-wear properties including Moly. This is for gearboxes

that are designed specifically for racing such as very thin gears

that handle very high horsepower engines that wear a lot. I would

say that in most cases I would run the 100% synthetic.

MS: I was told that

synthetic oil leaks out of the ZF if there is even the slightest

leak.

DW: In a nutshell,

synthetic is a bad word in a sense. For example, if you took white

sand and synthesized it, it would turn into glass. Nobody ever calls

glass synthetic sand. With engine oil there are two types of

synthetics. The main type in this country is a synthetic called

Polyalphaoefin which is a petroleum oil that is synthesized, which

is then called a synthetic because you have changed the structure.

It is called PAO for short and is relatively inexpensive at $4.00 a

quart. The second type is an ester. These are actually a vegetable

synthetic, coming from vegetable fatty acids and alcohol and

processed in laboratory conditions. They are true synthetics from

natural resources. Thus, there are two types of synthetics, one a

petroleum product and the other from vegetables. A synthetic will

find a leak A vegetable synthetic has a property we call

unctuousness or oiliness.. It is polarized and actually has a

negative end chain and iron and steel have a positive end chain.

What happens is that the oil is attracted to bare surfaces and is

trying to spread to wherever there isn't any oil. Thus if you have a

weak gasket, a good synthetic oil will capillary or migrate through

a weak gasket. That is one of the key advantages to an ester based

synthetic like we use. Once you put this type of product in you

never start metal to metal, even after a year there should be a one,

one millionth inch of film. Even if the car has been in storage.

This is completely untrue of petroleum oil regardless of who makes

it. Petroleum will come off just from it's own weight in time.

MS: How often should we

change the gearbox oil?

DW: I normally say,

depending upon the mileage. Once a year or every 12,000 miles. If it

is abused very hard, you start to destroy the extreme pressure

additive portion. We use a very special sulphurized ester. This is a

secondary type of extreme pressure additive sort of like a bullet

proof vest. Even after twenty years, if you don't get shot, it is

still there. But if your shot, so is the vest. It works in the same

way. Under extreme conditions when you have very high temp, caused

by the two gears meshing very hard, for example you should be in

first gear but you are in third, or going up a hill or having flat

tires. These are extreme conditions and the gears can get super

heated. The sulfurized ester when it gets super heated will actually

plate and becomes a solid and will decompose in a fraction of a

second but in that second, while decomposing, it will plate and

prevent metal to metal contact. If you really abuse the gearbox, I

would change it more frequently, like six months of six thousand

miles (for the street) but racers BEWARE, I'd change or at least

check the oil after a serious race weekend! That is real cheap

insurance.

MS: We just did a story on

a Pantera with 600 miles on it. How would you counsel owners that

plan on storing their cars or driving them the shortest of

distances?

DW: If that car has the

original seals in it, I would use the semi-synthetic gear oil, as

for the engine, having only 600 miles on it, it probably is only

started once in awhile. If somebody is starting an engine regularly

and allowing it to heat cycle, letting the oil reach all of the

parts, then you might want to go into our 6100 Synergie oil which is

a semi-synthetic oil. It is approved and homologated in 60

countries. It has some esters in it to keep a film on the engine

parts.

MS: What type of motor oil

does Motul offer that would be of the most interest to us 351-C

owners?

DW: We have two oils, a

semi-synthetic and a 100% synthetic. I would say that the

semi-synthetic has all of the current, modern day approvals which

isn't as critical on an older Pantera. If the car is raced I

recommend to use or at least mix in our Racing 300 V series. It is

an ester oil, which has a very high running temperature. The

advantages of the Racing 300 V, is again, the film that the ester

puts down and prevents metal to metal contact. A second advantage in

the 300 V series is that the ester has four to five times the film

strength and the tensile strength. It is more of an insurance

policy. Compare cooking with butter and cooking with olive oil. If

you leave the butter cooking too long in the frying pan, when it

gets too hot, the oil will evaporate at a certain point

(volatility), it will actually carbonize and leave a mess because it

has overheated. The ester has a very high running temperature of 365

degrees in the 300 V oil which will stand up to very high

temperature in an emergency. For example, what if you are driving

along and a hose comes off, a rock hits the radiator, a clamp comes

off, the water pump stops working, the thermostat sticks or any of

these things. What would you rather have in the crankcase in your

351, butter or olive oil?

MS: Why does 300 V

Racing oil cost more than off the shelf products?

DW: An ester based synthetic is not pumped out of the ground. They are

collected from vegetables, coconuts and Methyl products. It drives

the prices way up. Mobil 1 and Castrol are designed for modern

street cars. 300 V is designed for performance. Some of our products

may be designed for energy conservation but they will never have

energy conserving paramount and that is a complete difference in

theory. We like to have some resistance on the rings because the

rings are meant to seal. A total reduction of friction on the other

hand is not very good for internal combustion motors. You have to

have some properties to make sure the rings are sealing, etc. We use

a different additive package and a different base. Other products

are designed for moderate horsepower, moderate performance and

moderate compression. What we do with the 300 V is developing it for

high performance first not a mileage situation. The 300 V is the top

of our line and has major portions of research and chemistry

modification research going on constantly. It is constantly looked

at. We now have 10w40, 15w50 and 15w60 among others. This is for

different applications for different cars. Our 15w60 was made to

tackle fuel dilution problems in 24 hour racing like at LeMans.

After so much time, in the race, they get a lot of blow by and fuel

getting past the rings during the race. This will thin out the oil

so much that they had to actually create a 15w60 oil viscosity so

that by the end of the race there would be enough viscosity left to

hold or cushion the motor.

MS: What weight do you

recommend for the 351C that might hit the track now and then but

mostly sees street use on an infrequent basis?

DW: I would recommend a

15w50 for most performance vehicles except for cars like the new

Hondas that are very, very tight on the pistons and lifters. There

we use a 10w40 or 5/30. A 15w50 has a pour point of 22 degrees below

zero. An ambient temperature of 30 degrees Farenheit, and above

should be fine for a 15w50 oil. 10w40 is for lower temperatures.

With this oil, it will be almost impossible for the motor to destroy

the ester based portion of the oil. It almost is inshearable. That

motor won't place enough stress, even if it is built to destroy the

ester. The additive package is something we can't control. For

example, if an owner only starts his engine occasionally and doesn't

properly warm the engine up for long enough to get the oil

temperature past 160 degrees, it doesn't burn off any of the

impurities. At 160 the additives begin to work. At 180 degrees you

burn off all of the condensation. It starts to steam out to the

recirculating system. All of those contribute to the change time

when the owner never takes the car out for a long enough drive to

get it warm. This results in gas in the crankcase that never burns

off. I would recommend an oil change under those conditions even

sooner, for example 2,000 miles. I have checked the oil at 7,000

mile intervals and have not had any problems. However, I have had

cases where at 3000 miles there was sodium and coolant in the oil

and all kinds of stuff. It mostly depends upon the condition of the

car and who is driving it. I would say, 3-5000 miles on our 300 V

would be the average.

MS: Any advice for our

forced induction owners on oil?

DW: Yes, one of the

advantages of the ester based products is just like in our example

of the butter burning. If you burn that butter you get a carbon

mess. If you put olive oil in, even on fire, what it leaves behind

is almost nothing, there are very few coking deposits. The advantage

of 300 V is that the ester based products do not leave coking

deposits if they burn. What kills turbos and their bearings is not

only the heat, but when you shut the engine down, pumping oil to the

turbo stops, the races remain hot. When you look at the bearings

taken from heat affected areas, they have a brown haze on them and

what that is are the races cooking in the oil and building up a

film. When you go to start the engine again, the bearings rub that

film down but what you are starting to do is building a film on the

bearings and that is what kills the bearings because the oil doesn't

have space to take up or go around the race and eventually it will

squeeze so hard that it won't let any oil in as a flow and you break

the heat treat. The 300 V is very good for the turbos because it

doesn't leave deposits when the motor is shut off and cooling down.

MS: All we hear about are

additives, I am sure you have seen them on TV and seen the ads. Are

these of value to us Pantera owners?

DW: The Prolong additive

is a chlorinated hydrocarbon. What that means is that it is invested

with a chlorine process and it is petroleum oil. I understand that

this additive was developed before Prolong did it's marketing

campaign, it was actually made for Canadian jets and they needed

some type of a product that would prevent galling of bearings when

the aircraft would have to take off in the Tundra from an emergency

situation. Yes, it is an extreme pressure additive in a nutshell. We

don't use it because it is chlorinated. It is very ecologically

questionable. Motul is sold in 65 countries and most of them don't

care for its use. The United States has rules that pertain to too

much chlorination in waste oil which has to be handled special. We

are still testing this to determine how it affects the rest of the

engine oil such as anti-foaming and anti-corrosion. I haven't tested

it enough to say that it is detrimental. You don't need it in our

engine oil because we already put in extreme pressure additives. We

also test its ability to blend. You may only see the product in a

test situation but how does it react when there is gas or water

mixed in with it or deposits of carbon that wash by the rings or how

does it react with heat cycling? These are questions that we don't

have answers for.

MS: I feel like these

Motul products could actually save an engine in a crunch. Is that a

safe assumption?

DW: That is one of the

reasons why these products are so highly acclaimed and have a loyal

following, especially in Europe and other countries. Because of it's

characteristics, particularly it's very high boiling point and

running temperature, there is a situation where you have tight spots

or heat problems, it will go to it, which would prevent serious wear

or serious dilemmas. It is not going to prevent something from

happening it the component is already on it's way out or not put

together well enough. It might prolong something that is fatiguing

or cracking but it can't prevent it. If a motor is pushed very, very

hard and the film strength of the oil collapses or can't handle it,

that could be the start of a problem, such as the bearings beginning

to scuff because the running temperature of the oil couldn't hold

it. We have situations where a racer forgot to put water in the

radiator and went around Daytona for 7 laps before the driver

noticed something was wrong. Our product saved the motor.

MS: You have given us a

lot of good ideas. Summing our chat up, why should a Pantera owner

consider purchasing these Motul products?

DW: If you look on the

back of a container of Motul 6100 Synergie, our street version, you

will find that it has homologation from the major factories on it.

There are several types of approval for it, but what you really need

to look for is for longevity in the product, you need some type of

ester in the product. You need something that stresses performance

instead of lowering friction or increasing mileage. Because we are

looking more at a Pantera as a total performance package. It doesn't

necessarily mean removing all of the friction, there has to be a

balance. We have a complete line of products for automotive

applications. I define high performance as being more than just

changing the oil, the oil must be looked at as being more than just

maintenance and instead as insurance. This means that if you use our

300 V Motorsports oil, even if you mix it with our 6100 Synergie

oil, which I have people doing, you will find that it is real good

piece of mind knowing that if some situation occurs where you are

running our top of the line products, that you will stand a much

better chance of sustaining only superficial damage instead of

having to replace an entire motor type of damage.

MS: Thank you for your

time in granting us this interview. Now I finally understand why our

Pantera was able to finish and win so many races in Europe. Those

Motul lubricants kept it running on the last lap.

DW: These lubricants are

cheap insurance.

MS: We strongly

recommend and use these phenomenal products in all of our DeTomaso

cars and our racing cars as well.